Diamond Wipes achieves greater labeling efficiency with centralized control, reduced ink costs, and an anticipated quick-turn ROI

Faced with a sudden, steep increase in demand due to COVID-19, Diamond Wipes implements a Matthews Marking Systems coding solution allowing them to substantially scale their operations while simultaneously increasing efficiency and reducing operational costs.

Summary

Adaptability and agility are critical assets for any business, but today—with the additional challenges created by COVID-19—they are more important than ever. The global pandemic forced a fundamental shift in how companies do business, regardless of the industry they serve. Many had to adapt to a completely digital operation almost overnight while some were forced to develop new delivery models. And others faced an unprecedented surge in demand.

Diamond Wipes experienced an exponential increase in demand for their cleaning products as the coronavirus took hold all across the globe. To help respond to the situation, Matthews Marking Systems (MMS) helped Diamond Wipes quickly replace their existing coding system to deliver:

- Centralized control to boost efficiency

- A 30% cost savings on ink

- An anticipated quick-turn ROI

The Challenge

Diamond Wipes is a U.S.-based manufacturer of sanitizing wipes that offers contract manufacturing to a variety of industries (foodservice, hospitality, cleaning, healthcare, and beauty) as well as their own premium and value wipes for the consumer market. They’ve been in business for nearly 25 years, and are very proud to feature made-in-America products.

When COVID hit, Diamond Wipes pivoted to operating in the new norm while witnessing an astonishing increase in demand for one of their biggest product lines – the individual wipe packets included in many first-aid kits.

Diamond Wipes’ existing coding system had several critical shortcomings. Most importantly, it could not scale to meet the surge in demand. Because the system was neither centralized nor capable of integration with the rest of the production systems, expanding their operations simply wasn’t feasible.

Additionally, the legacy system was truly inefficient. Its clunky, standalone user interface (UI) required floor operators to manually make changes across fifteen individual printers each time a code or date needed to be updated. Not only was this process incredibly time consuming, slowing production on a regular basis; it also increased the risk for potential coding errors.

Diamond Wipes knew a more efficient and modern coding solution must exist, one that would positively impact their bottom line while driving efficiency gains in operations and ink consumption.

The Solution

Matthews Marking Systems’ MPERIA® controller with VIAjet™L-Series thermal inkjet (TIJ) printer offered Diamond Wipes everything they needed to modernize their production line for greater efficiency and cost effectiveness while also providing a seamless method to scale operations and meet growing demand.

Accuracy, Speed, and High Resolution

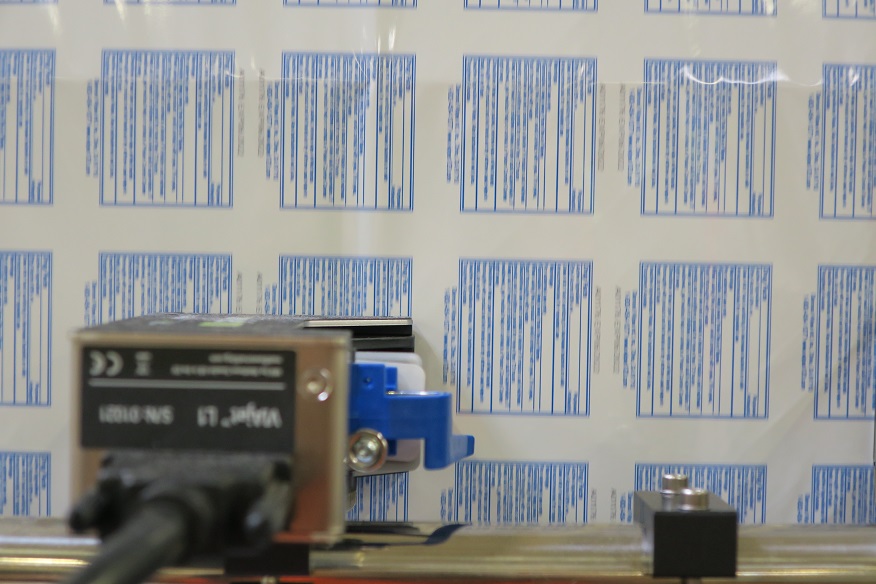

Diamond Wipes chose the L1 VIAjet printer, an ultra-compact, high-performance printhead, perfect for tight spaces and OEM integration. It’s an excellent solution for high-resolution codes up to 2mm (as well as larger codes and text up to 6mm), and ideal for the kind of high-speed commercial printing done at Diamond Wipes.

In addition to unmatched speed and quality, the VIAjet L1 also helps Diamond Wipes positively impact their bottom line with superior ink utilization. Droplets of ink from the L1 printhead are smaller, translating to a yield advantage of nearly 30% over comparable HP cartridges. And because cartridge changeover is easy and happens less frequently, Diamond Wipes saves on routine maintenance costs and reduces downtime.

Flexible Integration Options and Scalability

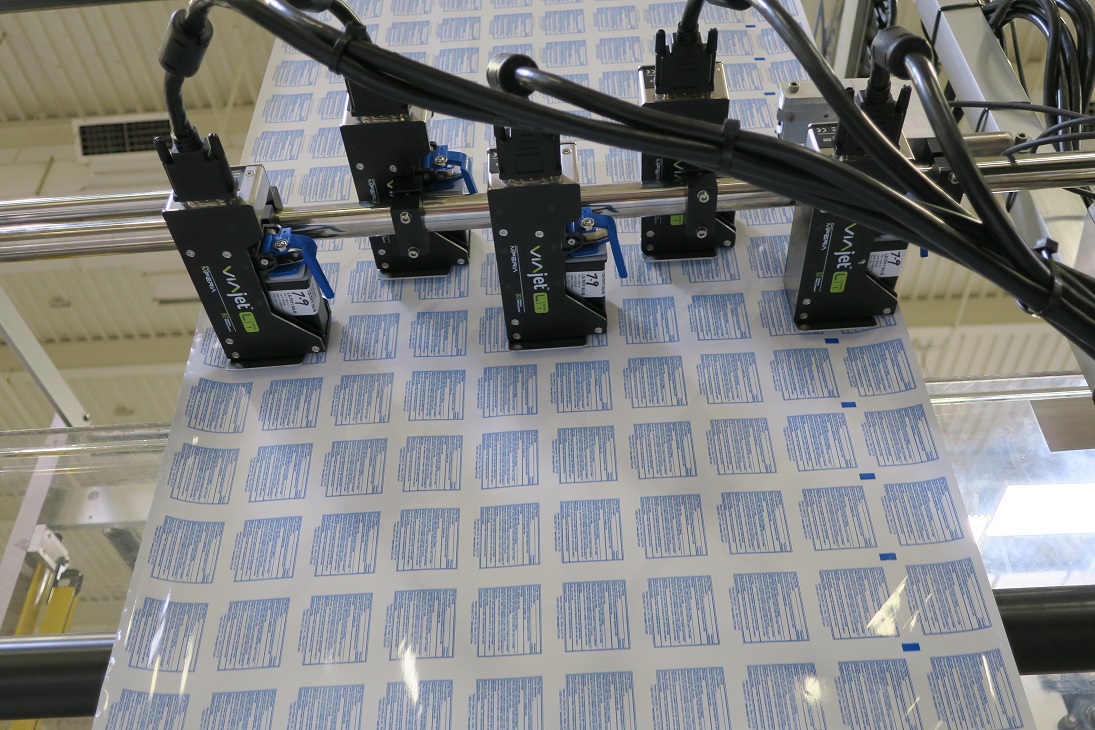

Perhaps the most appealing feature of the MMS solution is seamless scalability. The compact, low-profile system is fully networkable, allowing Diamond Wipes to connect all necessary components to a single MPERIA controller via Ethernet. True scalability enables Diamond Wipes to easily expand their production capacity, adding printheads as needed.

Efficient Centralization, User-friendly Interface, and Remote Access

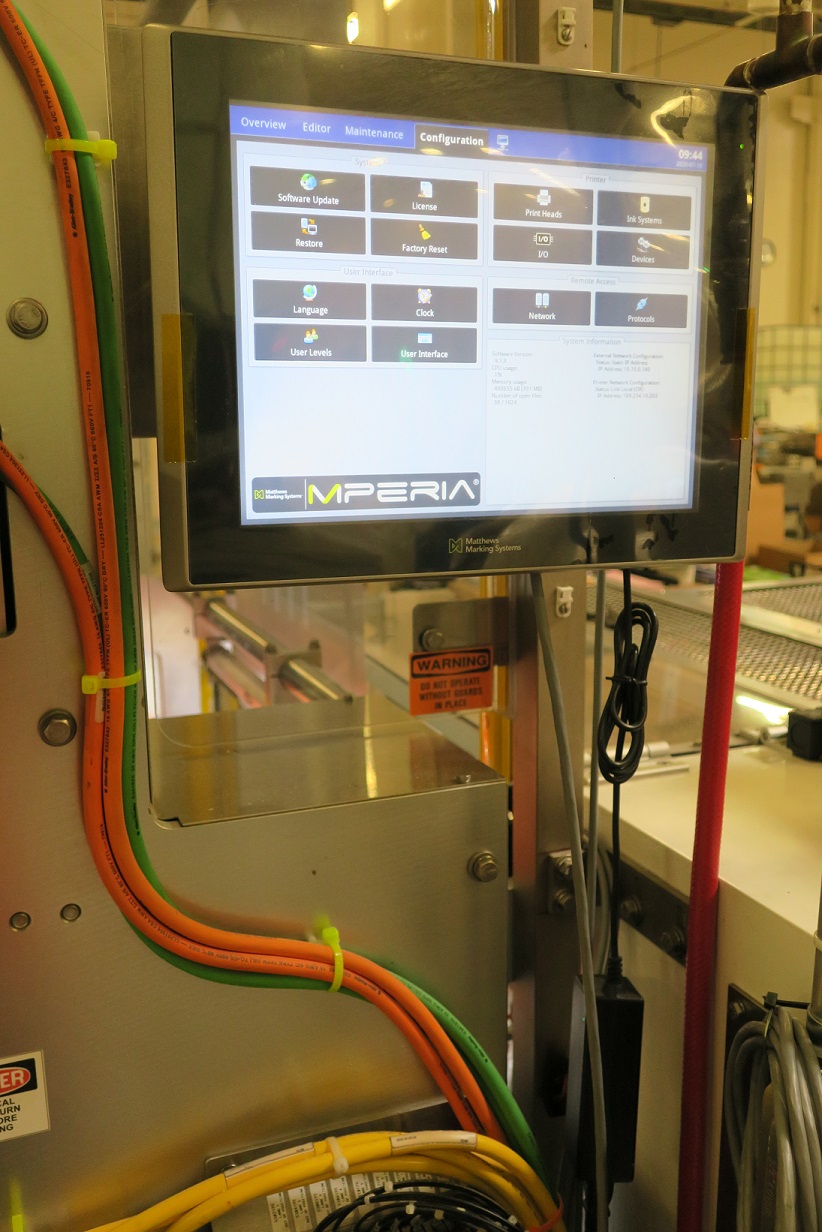

Unlike Diamond Wipes’ legacy system, the MMS MPERIA platform integrates easily with existing systems—virtually any ERP, MRP, or database. Because there’s no middleware or third-party hardware required, Diamond Wipes was able to manage the integration quickly and with very little effort.

Once integrated, the MPERIA platform centralizes control of all the L-Series units so that making changes is painless. Instead of having to make the same change on multiple printers—slowing production and risking errors—the operator makes one change at the MPERIA controller, instantly updating all the printers on the line.

The MMS solution also gave Diamond Wipes the convenience of VNC (virtual network computing)—allowing remote management of the system from anywhere. This is especially relevant as production lines run five days per week, two shifts per day. Reliable, 24/7 remote access ensures consistently smooth operations and tremendous peace of mind.

The Results

Diamond Wipes was up and running with their new MMS solution in a couple of days. Their staff handled the installation without middleware or third-party hardware. The commissioning to set up the line, controller, and VNC also only took one day.

Fast, Easy Scalability

Diamond Wipes initially implemented five MMS printers at their California location. They were so pleased with the initial results that they quickly installed five more printers in that facility and five additional printers at their Ohio location. Their plan is to expand this solution to their full production capacity, between 40 and 50 printers across two facilities. Flexible and scalable, the solution facilitates the easy addition of printers for Diamond Wipes, ensuring they’re always able to meet a surge in demand.

Centralized Control

The MPERIA platform gives Diamond Wipes efficient, centralized control of all the printers on their production line through a simple, user-friendly interface. In addition, it allows for remote access via VNC so that operators not only maintain social distance protocols while on the production floor, they can also see and manage what’s happening even when they aren’t on site.

Cost Savings and Quick-turn ROI

Diamond Wipes realized cost savings in three areas with their Matthews Marking Systems solution:

- Lower Ink Costs: Superior ink utilization, as compared to HP cartridges, allows Diamond Wipes to generate 30% more printable quantity for the same cost.

- Lower Maintenance Costs: Easy-to-change cartridges and reduced frequency of changes helps Diamond Wipes reduce expenses related to regular maintenance and upkeep.

- Greater Overall Efficiency: The centralized control, speed and accuracy of the printing process, and seamless system scalability all contribute to an overall increase in Diamond Wipes’ production efficiency.

All of these cost savings combine to deliver an anticipated quick-turn ROI.

“Our new Matthews Marking Systems labeling solution has transformed our ability to adapt to changing needs with ease and efficiency,” says Ciprian Cretu, VP of Engineering for Diamond Wipes. “The MPERIA system integrated seamlessly with our other systems, requiring very little from our team to get up and running. And the added convenience of having remote VNC access helps us stay on top of production no matter where we are. Our entire team is very pleased with the performance of the system and the value it delivers to our organization.”

About

Founded 24 years ago by a Taiwanese immigrant, Diamond Wipes has been proudly producing American made products to a wide array of prominent customers, including many of the world’s top 50 beauty and personal care brands. In addition to OEM manufacturing, Diamond Wipes distributes their own premium and value brands of wet wipes for professional use in industries including foodservice, hospitality, cleaning, and healthcare.