MPERIA® an automated, centralized, and adaptable marking and coding platform.

Invest a couple minutes of your time to learn how a marking and coding controller can lead to measurable results on your whole production line, from product to pallet!

Centralization of automation allows production line staff to spend less time resolving marking and coding errors and enhancing overall productivity. Generally, the cause of rework and scrap on a production line is human error; removing this risk and enabling centralized automation through a single touchpoint delivers real results – both in terms of cost savings and effectiveness of production staff. Introducing data automation to any production operation manually coding or messaging their primary, secondary, or tertiary packaging can drastically increase productivity and overall efficiency.

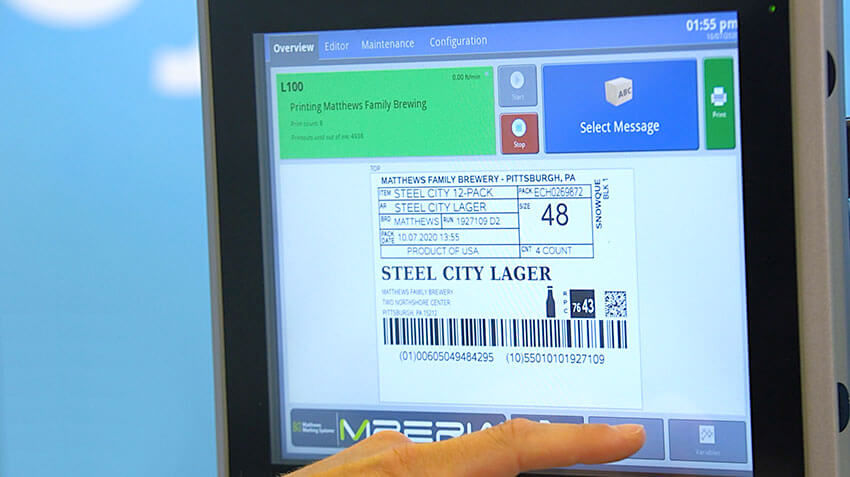

Whether operating a single printer on a single production line or multiple print technologies across many lines, the MPERIA®️ platform is the industry’s only universal marking and coding controller that can do it all from one central location. From easy message creation to marking automation, MPERIA gives you seamless integration with your backend business systems (as well as PLCs) and reliable operation day in and day out. Connect third-party printers or vision systems for tracking and code validation without hassle; MPERIA is as simple or as sophisticated as you need – it does it all, so you don’t have to.

Control All Marking Across One or More Production Lines

Improve productivity.

MPERIA delivers a single touchpoint for controlling Matthews Marking Systems’ printing technologies as well as third-party printers or labelers. Data can be automated from PLCs, ERPs, and other backend business systems ensuring accurate coding across all packaging. It seamlessly integrates with auxiliary equipment (scanners, scales, vision systems), enabling product-to-pallet verification of production line flow.

Reduce error and cost.

MPERIA enables operators to change coding on the entire line from a single location with an intuitive color touchscreen that’s easy to learn and can limit functions based on user level. Removing one of the leading causes of scrap and rework in the production facility: human error. Additionally, unintentional messaging mistakes introduce a serious implication in the case of product recall; companies could be subject to severe fines and even criminal charges. Automating data flow with MPERIA removes these risks, allowing production staff to focus on meeting their goals.

Future-proof your investment.

As your production operation grows and you add additional lines, the MPERIA platform grows with you. The platform easily scales to control additional printers on additional lines with nearly unlimited message creation capabilities, giving unprecedented scalability and flexibility. And when business systems need to be integrated, MPERIA seamlessly enables data automation from those systems – without the need to invest in any form of middleware.

Find the MPERIA controller best suited for your environment.

Check out all the different MPERIA controller options available.

See how MPERIA made a difference for our customers.

Learn how a Worldwide Produce Brand Achieves Major Productivity Gains and Cost Savings.

Get the specifics on how MPERIA helped a Sunkist Co-Packer Improve Traceability.